Revitalization of Barriques

Unlock the power of Barrique-Plus technology to double the lifespan of your oak barrels, conserve resources, and save up to €1,350 compared to purchasing a new barrique—all while maintaining the same flavor infusion and product quality.

AKTION NACHHALTIGKEIT 2024

– Barrique Revitalisierung & Toastung –

Mit Zufriedenheitsgarantie!

Process steps

Our comprehensive Barrique-Plus method comprises four application steps for thorough and gentle reconditioning of your wooden oak barrels:

Our competent expert team not only removes 100% of the tartar from the staves and heads of your barrels but also toasts the barriques to the toast grade of your choice, including bottom toasting.

Your barriques will be returned to you free of harmful yeasts and bacteria, ensuring a germ-free environment for immediate refilling.

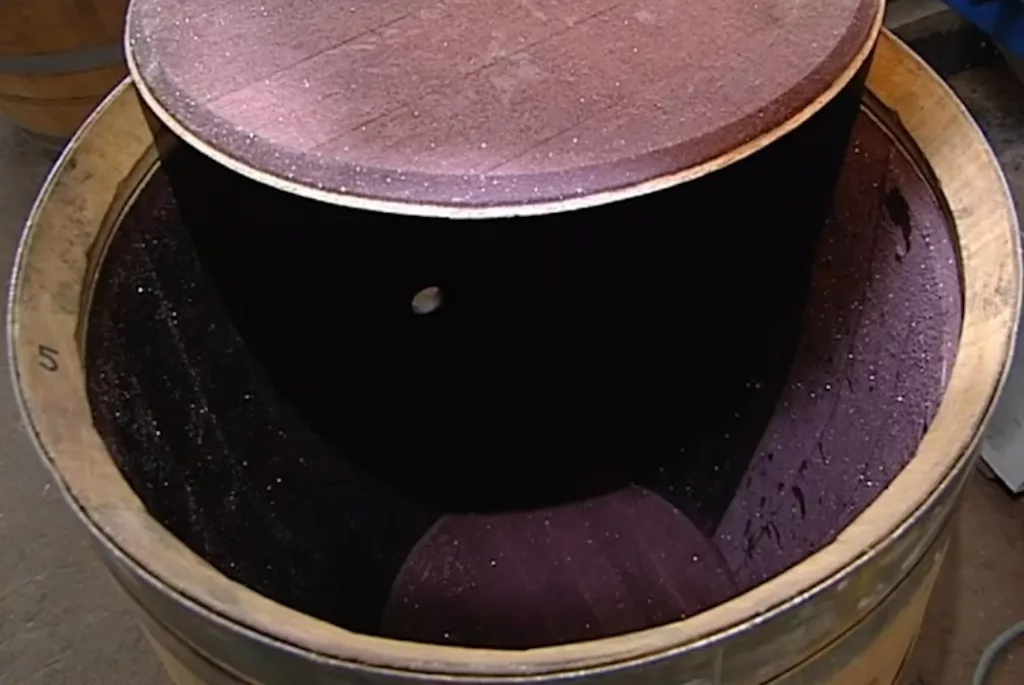

Dismantling of a barrel bottom and visual inspection

No barrique, no cask is alike; each wooden barrel holds its own unique story! The wood's characteristics are shaped by wood type, origin, prior use, and many other factors.

A meticulous visual inspection of the barrel and its interior immediately after expertly dismantling one of the barrel bottoms provides our trained staff with precise insight into the condition of the barrique and the required intensity of the cleaning process to ensure perfect refillability

High-pressure water jet milling with the Barrique-Plus technology

Our gentle Barrique-Plus high-pressure milling process combines profound expertise and extensive experience with computer-controlled control and regulation technology.

Years of expertise and the results of the visual inspection allows our skilled team to determine the optimal water pressure for cleaning each barrique – up to 300 bar, depending on the level of contamination and condition of the barrel – as well as other relevant settings of the system for perfect removal of deposits and depleted wood layers.

This ensures that any deformities and irregularities on the staves and at the bottom of the wooden barrel are completely balanced, maintaining a constant distance between the nozzles and the surface to be cleaned, resulting in a uniform jet milling effect

Our sophisticated technology ensures thorough removal of the deposits of all surfaces of your wooden barrel, including the area between stave ends and bottom, as well as hard-to-reach areas, without causing damage to important barrel parts, such as the groove.

Hot airstream toasting approach

With our thermal toasting process, we ensure that your barrels receive a uniform and reproducible toasting of the entire inner surface!

Unlike the common conventional methods of charring the wooden barrel over a fire or with the use of a gas flame, Barrique-Plus toasts the already milled barrels using an electrically heated, circulating airflow.

The use of electrically generated heat offers a crucial advantage: In addition to the duration of the toasting process, temperatures are also adjustable and precisely controllable. We enable heat treatment of up to 300 degrees.

Throughout the process, sensors continuously monitor the temperature at various points inside the barrel, providing precise information. This allows us to effectively regulate temperature fluctuations and avoid inconsistent toasting results.

The control of temperature and duration of treatment allows Barrique-Plus to achieve the finest 'toasting' gradations, surpassing the usual 4 toast levels of standard procedures. Depending on the selected toast level, the wood undergoes changes in depth from 2mm (light) to 4mm (heavy).

The 'toasting' method employed by Barrique-Plus allows for a homogeneous toasting of the inner surface of your barrels and exposes the pores without risking burnt wood or blister formation.

Assembly of the barrel bottom and cleaning of the exterior

The assembly of the remaining barrel bottom and the cleaning of the barrel exterior using a specialized brush, which removes dirt particles and creates a clean and appealing appearance, constitute the final step in our holistic, professional reconditioning of your barrique.

Of course, the alignment of the barrel hoops is included in the process, as attention to every detail is of utmost importance to us.